Measuring tank levels in industrial applications is a difficult task to carry out with repeated accuracy and reliability. We can continue to make use of the inexpensive traditional stick made of wood, metal, or plastic and inspect it by our sense, but it’s labor cost and easy to error-making due to the manual reporting methods. In some applications, the submersible sensor is also not an ideal optimal choice to measure levels in tanks with corrosive, boiling, and hazardous chemicals. However, a wireless ultrasonic distance sensor is the best option that does not come into contact with the fluid itself, minimizing the potential of false reading caused by corrosion. Ultrasonics is the science of sound waves above the limits of human audibility.

There are many kinds of technologies in the market with accuracy, reliability, and costs, such as the optical method, radar method. But they are not the best answer to seemingly intractable problems of reliable level measurement for applications where an ultrasonic solution is needed.

Challenges

- Sensors can get dirty over time and users are not able to measure at all

- Sensors are dependent on human labor to measure levels, which means the risk of error and danger

- Sensors are much higher in price than the ultrasonic distance/level sensor

Featured Product

Sensors are just like sensing organs of a technical system. From the various types of sensors, the most common use sensor for obstacle detection and its distance measurement is the ultrasonic distance/level sensor. Ultrasonic distance/level sensor uses ultrasonic technology that measures sound waves for its ranging and the speed of sound is influenced by several environmental parameters.

Milesight offers an ultrasonic distance/level sensor with extremely accurate to 1% of the detected range. The non-contact, liquid level sensors can work for compact tanks with measuring ranges from 0.3 meters up to 10 meters and work in a variety of hazardous locations approvals to meet the demands of chemical processing industries.

- EM500-UDL Ultrasonic Level LoRaWAN® Sensor

The EM500-UDL sensors are ideal for the most popular application that is measuring the level or volume of a body of liquid in a tank and container. If the vessel is linear, estimating volume is easy.

Solution

The ultrasonic distance/level sensor can mount at the top of the tank and face down toward the liquid surface. It works on the principle that uses ultrasonic pulses to generate a signal. The signal transmitted from the sensor is reflected from the surface of the medium and transmitted back to the sensor. By measuring time, knowing the distance between the ultrasonic liquid level sensor and the surface of the medium to determine the liquid level, tank height, and volume of liquid.

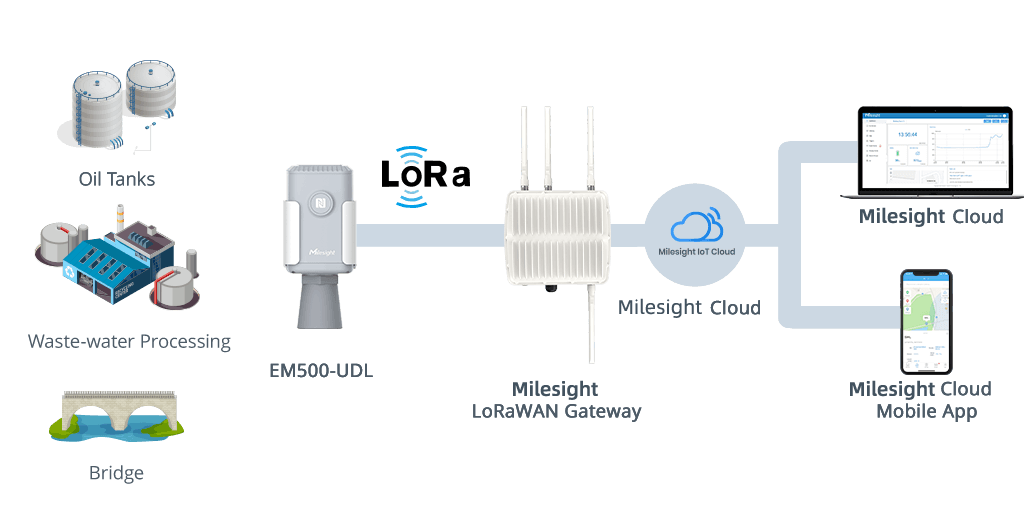

The LoRaWAN® based ultrasonic distance/level sensor can collect data and send it to the base station wirelessly. Its built-in lithium battery-powered design can save your maintenance troubles and significant cost in day-to-day usage.

The level data can be displayed on the Milesight Cloud platform or transferred to the third party’s application server for viewing by admins.

Benefits

Sustainable High-performance Design

Reduction of sensor fouling or corrosion caused by chemical objects.

Guaranteed Data Accuracy and Reliability

Free from the disturbance of surface color or optical reflectivity of the object. The accuracy of the reading remains unaffected even after changes in the chemical composition of fluids.

Ease of Use

Easy installation on the structure of the tank over the liquid. Removable, reusable, and leaves no cable and mess.

Cost-Effective Solution

Little power consumption and relatively inexpensive.