Automated Guided Vehicle (AGV) is a portable robot that has been used extensively to simplify intralogistics and material handling processes in industrial environments without an onboard operator or driver. The first known AGV was introduced by Barret Electronics of Northbrook in 1953. At the time it was simply a tow truck that followed a wire in the floor instead of a rail. Since then, new technologies renew AGV to enhance its performance and capability over and over again. However, due to the shortcomings of connectivity solutions like Wi-Fi, requirements on latency and reliability of communication link cannot satisfy the need of AGV which limits the performance and capability of AGV. But it changed in the era of 5G. Armed with 5G, AGV unlocks its potential.

5G Solution for Automated Guided Vehicle

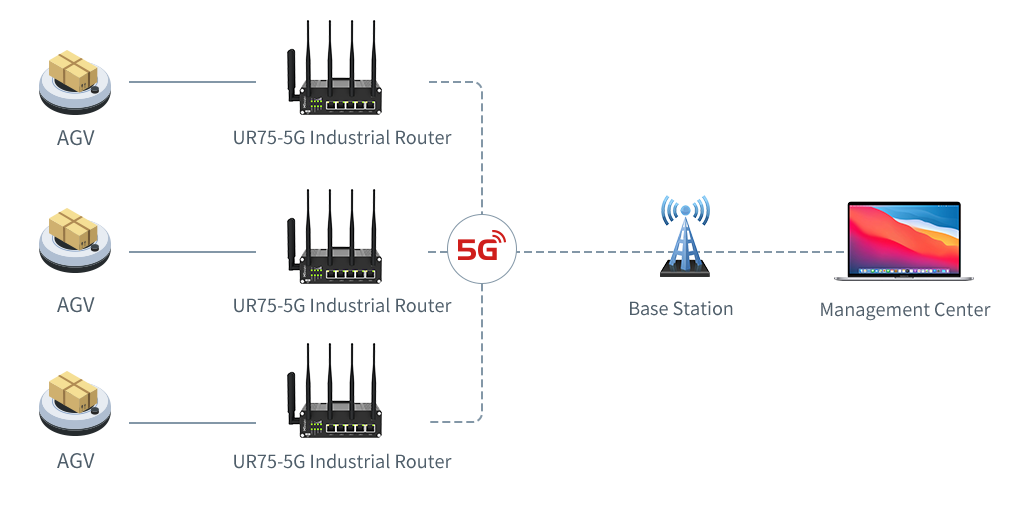

5G, the 5th generation mobile network, has features of high performance, high reliability, high speed and low latency which enhance the performance and efficiency of AGV in a colossal of applications. While be integrated into the AGV, Milesight UR75-5G, an intelligent industrial IoT router, provides a stable and reliable 5G network for AGV.

How 5G Empowers Automated Guided Vehicle

1. Strengthening the coordination of AGVs

5G offers a high-speed and low latency network for the communication between AGVs, making AGV robots have a high level of self-fleet-organization and cooperation. Hence AGV robots can simultaneously cooperate to achieve tasks that a single AGV robot could not perform alone in the past.

2. Improving Safety in Human-Machine Interaction

The features of 5G’s ultra-low latency enable AGV robots to perceive and forecast worker’s behavior and movement to maintain a safe distance with workers to ensure safety.

3. Real-time Remote Control

5G guarantees real-time control of AGV which is essential to prevent workers from injury for dangerous tasks in harsh environments such as high temperature and high-pressure plants.

4. Real-time Data Collection and Analysis

The 5G network can interconnect vast amounts of AGVs to collect data such as the time of logistics handling, the location of stay, the trajectory of movement, and so on. Data can be collected and analyzed in real-time to improve the manufacturing process and achieve high efficient fleet management.