Stronger demand for customization, increasing customer expectations, the complexity of the global supply chain – these and many other challenges encourage manufacturers to find new, more innovative ways to remain competitive. In an attempt to gain productivity improvements and uncover new ways of enhancing manufacturing and supply chain operations, businesses resort to digital transformation.

Industrial Internet of Things (IIoT) is a way to digital transformation in manufacturing. Industrial IoT employs a network of sensors to collect critical production data and uses cloud software to turn this data into valuable insights about the efficiency of the manufacturing operations.

IoT adoption in Manufacturing

The main adoption drivers for the Industrial IoT solutions include:

- Cost reduction. Due to optimized asset and inventory management (hence, lower inventory carrying costs and search times), reduced machine downtime, more agile operations, and more efficient energy use, companies reduce operational costs and create new sources of revenue. For instance, smart, connected products allow to shift from selling products to selling experience – product usage and post-sale services.

- Shorter time-to-market. Faster and more efficient manufacturing and supply chain operations allow reducing product cycle time. Harley-Davidson, for instance, leveraged IoT to reconfigure its York, PA manufacturing facility and managed to reduce the time it takes to produce a motorbike from 21 days to 6 hours.

- Mass customization. The mass customization process requires a dramatic increase in the variety of produced SKUs, which causes inventory to go up and become more diverse. Manufacturing operations get more complex as well – the production of 20 items of SKU X can be immediately followed by the production of 10 items of SKU Y. Tracking the inventory and the manufacturing operations becomes burdensome and, in some cases, not feasible. IIoT facilitates mass customization by becoming a source of real-time data required for thoughtful forecasting, shop floor scheduling and routing.

- Improved safety. IIoT helps to ensure a safer workplace. Paired with wearable devices, IIoT allows monitoring workers’ health state and risky activities that can lead to injuries. Along with ensuring workers’ safety, IIoT addresses safety problems in potentially hazardous environments. For instance, in oil and gas industry, IIoT is applied to monitor gas leakages as it travels through the pipe network.

IIoT adoption in numbers:

CGI’s study reports that 62% of surveyed manufacturing enterprises are already executing digital transformation pilots and programs.

Bsquare annual IIoT maturity survey reports that 86% of manufacturers have already adopted IIoT solutions, and 84% of them find IIoT extremely effective.

McKinsey estimates that IoT applications in manufacturing are expected to generate $1.2 to $3.7 trillion of economic value annually by 2025.

Three dimensions of IIoT’s impact

IoT technologies are transforming the way production systems are built and run, driving improvements across three main dimensions of the digital transformation:

- Dimension 1. Visibility into shop floor and field operations

- Dimension 2. Visibility into the manufacturing supply chain

- Dimension 3. Visibility into remote and outsourced operations.

In the subsequent sections, we’ll have a closer look at each of the digital transformation dimensions and explore them from the IIoT applications perspective.

Dimension 1. Visibility into the shop floor and field operations from the top floor

The Industrial IoT offers the revolutionary level of visibility into the shop floor and field operations, as well as the possibility of handy control over enterprise resources. IIoT technologies fill the gaps that lead systems like ERP and MES to come to their limits: the reliance on manual data input and the inability to work with detailed information (real-time equipment status records, inventory items’ location, etc.)

By providing manufacturers with second-by-second shop floor data, IIoT allows businesses to considerably increase manufacturing process productivity. IBM reports that using IIoT insights for manufacturing process optimization can lead up to 20% higher product count from the same production line.

The IoT applications that allow manufacturers to gain a higher level of vertical visibility fall into two groups:

- Applications supporting manufacturing operations

- Applications facilitating industrial asset management.

IoT-driven manufacturing operations

According to an a McKinsey research, by 2025, the improvements in operations driven by IoT applications could be worth more than $470 billion per year. IoT applications for manufacturing deal with such operations as monitoring and optimizing equipment performance, production quality control, and human-to-machine interaction.

Monitoring equipment utilization

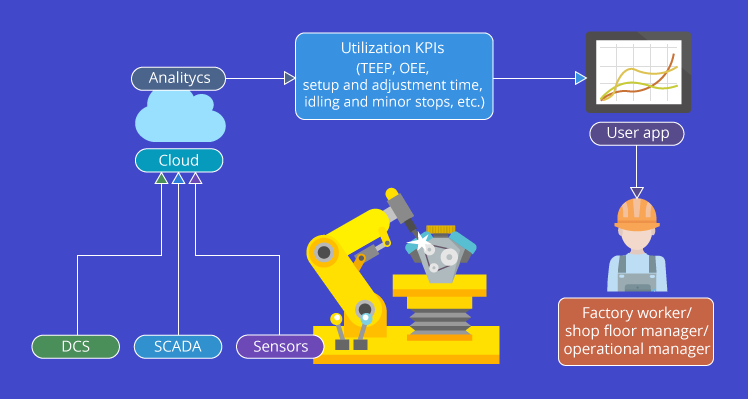

As ITIF research reports, IoT applications for monitoring machine utilization can increase manufacturing productivity by 10 to 25% and produce up to $1.8 trillion in global economic value by 2025. IoT solutions for monitoring machine utilization provide businesses with real-time equipment utilization metrics, thus offering a detailed view of what is occurring at every point of the production process.

Monitoring machine utilization starts with pulling relevant data about machine operating parameters, e.g., run time, actual operating speed, product output, etc., from sensors, SCADA or DCS systems. The data is gathered in real time and transmitted to the cloud for processing. The cloud aggregates the data and develops it into informative insights about equipment utilization KPIs (TEEP, OEE, setup and adjustment time, idling and minor stops, etc.). After the data is analyzed, the results are visualized and displayed to the factory workers via a user app (either web or mobile).

We deployed a machine utilization monitoring solution that helps us improve productivity and optimize the utilization of computer numerical control (CNC) machines. The IIoT solution we deployed uses real-time data from equipment sensors to provide reports on the machines’ cycle times, the number of parts produced, downtime, and other utilization metrics.

BC Machining LLC, a metal parts manufacturer

Product quality control based on condition monitoring

Monitoring the quality of the produced goods can be carried out in two ways: by inspecting a WIP (work in progress) as it moves through the production cycle or by monitoring the condition and calibration of machines on which a product is manufactured. Although quality control based on inspecting WIPs provides more accurate results (it helps to uncover minor defects, say, inaccuracies in parts alignment), there are certain limitations that hinder the method’s usage:

- Quality control based on WIP inspection is applicable only for discrete manufacturing.

- It is costly, time- and labor-intensive, as the WIPs are inspected manually.

- It is rarely possible to inspect every WIP, therefore, the method provides a fractional view.

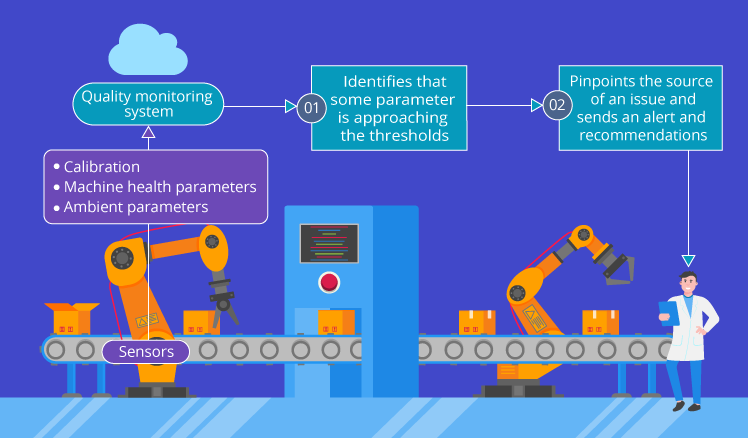

The second method, based on monitoring the condition and calibration of machines, offers less differentiation in terms of scope - it provides simple binary classification “good” and “not good”. However, it helps to detect bottlenecks in the manufacturing operations, identify badly tuned and/or underperforming machines, timely prevent machine damages, and more.

To monitor the quality of the production process, such parameters as equipment calibration, machine conditions (speed, vibration, etc.) and environmental conditions (temperature, humidity, etc.) are monitored to identify when they go beyond the normal thresholds. If sensor readings are approaching the thresholds that can lead to a potential product defect, a quality monitoring solution pinpoints the source of an issue, triggers an alert and recommends a mitigating action to fix or tune the machine and minimize the production of low-quality products.

We have turned to IoT development to monitor the quality of produced paper. We rolled out the network of temperature and vibration sensors to monitor the condition of press rolls particularly critical for the quality of produced paper, which helped the company to minimize the amount of low-quality yield.

Maastricht Mill, a paper producing company

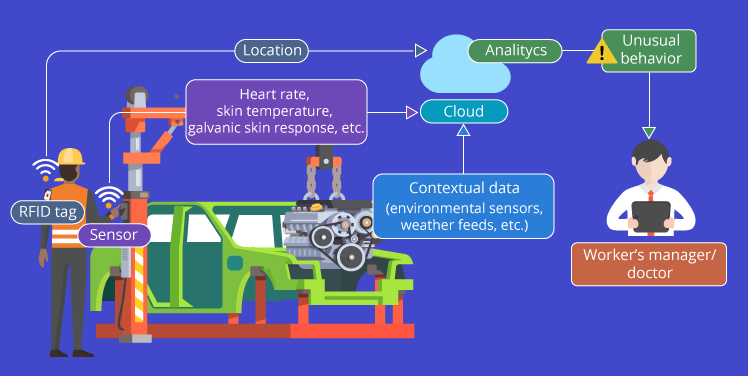

Monitoring safety

In various industrial sectors, including mining, oil & gas, transport, etc., workers receive RFID tags that gather data on their location and wearable sensors collecting data about their heart rate, skin temperature, galvanic skin response, and other parameters. The sensor data is relayed to the cloud where it is analyzed against contextual data (e.g. from environmental sensors, legacy work planning systems, weather feeds, etc.) to detect unusual behavior patterns (say, sudden vertical movements, unusual heart rates, etc.), and prevent workers from falls, overexertion, and other injuries and timely report a safety threat.

For instance, a combination of high skin temperature, a raised heart rate, and no movement patterns for about a minute could indicate that a person suffers from overheating. Whenever such a situation is recognized, an IoT solution notifies an employee’s responsible person (a worker’s manager, a doctor, etc.) via a mobile application.

To ensure our workers’ safety, we leverage a safety monitoring solution powered by IBM’s Watson IoT. The solution uses a range of sensors, including accelerometers to measure workers’ movements and detect falls, heat sensors and heart rate measuring devices to help detect overheating and fatigue. With safety monitoring solutions, we managed to reduce the number of workplace injuries and diminish their severity, not to mention the increase in profit margins by at least 40 percent.

Nation Waste, Inc., a waste disposal company

IoT applications for industrial asset management

Along with improving the effectiveness of manufacturing operations, the Internet of Things is applied in manufacturing to ensure proper asset usage, extend equipment service life, improve reliability, and provide the best return on assets. The IoT applications facilitating industrial asset management include:

- Industrial asset tracking

- Inventory management

- Predictive maintenance (based on condition monitoring).

Industrial asset tracking

According to Zebra’s 2017 Manufacturing Vision Study, smart asset tracking solutions based on RFID and IoT are expected to overtake traditional, spreadsheet-based methods by 2022. By providing accurate real-time data about enterprise’s assets, their statuses, locations and movements, IoT-based asset management solutions remove the tracking burden from the employees (freeing up to 18 hours of monthly working time) and eliminate errors bound to the manual methods of data input.

To enable asset tracking for manufacturing, IoT works together with RFID. Each asset – be it a magnetic locator or a crane – gets labeled with an RFID tag, which serves as an asset identifier. Each tag has a unique ID, which is linked to the data about a particular asset. Both the ID and the corresponding asset data is stored in the cloud. The asset data may include the asset’s physical parameters, cost, serial number, model, assigned employee, area of use, etc.

Once an asset, say, a crane, leaves an equipment storage yard, an RFID reader installed at the yard entrance, scans the tag attached to the crane and saves the record about the asset leaving the yard to an in-cloud database. Similarly, when the crane enters, say, a construction site, an RFID reader at the construction site entrance scans the tag and updates the data in the database. Logging such data throughout the asset’s journey allows technicians to see the movements of the assets.

![]()

Along with that, GPS tracking can be used to state the location of the movable assets, for instance, machines used in construction. For movable items, asset tracking solutions are also used to calculate utilization. For instance, seeing for how long each movable (say, a bulldozer) is in use, technicians can pinpoint idling or underused machines and schedule preventive maintenance.

We turned to IoT development to implement a smart asset management solution. Now our employees use a mobile app to see where all of their assets are located. The managers can see how many tools and pieces of equipment are at a jobsite and who operates them. With real-time data on the tools’ usage and location,we have achieved a higher level of asset visibility and accountability, as well as saved our employees vast amounts of time previously spent on manual tracking and searching for the tools.

VerHalen Inc., a construction company

Enterprise inventory management

IoT-driven inventory management solutions help manufacturers automate inventory tracking and reporting, ensure constant visibility into the statuses and locations of individual inventory items, and optimize lead time (the time between an inventory order and its delivery). Due to these improvements, smart inventory management solutions are reported to save 20% to 50% of an enterprise’ inventory carrying costs.

Inventory management solutions applied in the manufacturing settings are based on IoT and RFID technologies. Each inventory item gets labeled with a passive RFID tag. Each tag has a unique ID that carries the data about the item the tag is attached to. To fetch the data from the tags, RFID readers are used. A reader catches tags’ IDs and relays them to the cloud for storing and processing. To establish the location and the movements of the scanned tags, along with the tags’ IDs, the data about the location of the RFID reader and the time of the reading are relayed to the cloud. The cloud pinpoints the location and the status of each item, visualizes the findings and displays them to the users.

We implemented an inventory management solution based on RFID and IIoT. As we produce finished foam products, they are labeled with RFID-tags. This allows us view inventory levels in real-time, locate specific inventory items and automate inventory tracking processes that were previously handled manually.

Sekisui Alveo AG, a manufacturer of high-performance polyolefin foam materials

Predictive maintenance, condition monitoring

According to Deloitte, predictive maintenance solutions based on the Industrial IoT are expected to reduce factory equipment maintenance costs by 40% and generate the economic value of $630 billion annually by 2025. The solution leads the IoT adoption – 55% of businesses are at least piloting predictive maintenance projects. This is how it is carried out from the technological perspective.

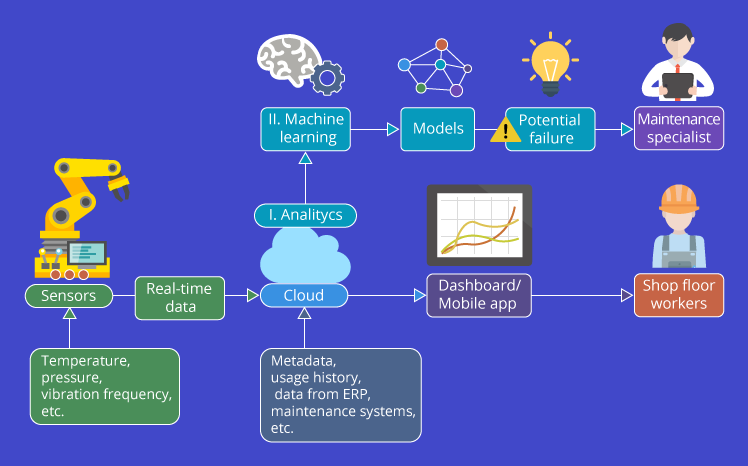

Predictive maintenance relies on the insights gained with continuous equipment condition monitoring. A piece of equipment gets sensors, which collect data on a wide range of parameters determining its health and performance, e.g. temperature, pressure, vibration frequency, etc.

Once collected, the real-time data from multiple sensors is transmitted to the cloud, where sensor readings are combined with metadata (equipment’s model, configuration, operational settings, etc.), equipment usage history, and maintenance data fetched from ERP, maintenance systems and other sources. The whole of data is analyzed, visualized, and presented to shop floor workers on a dashboard or in a mobile app.

However, mere reporting and visualization is still far from prediction. To enable prediction, the combined data set is run through machine learning algorithms to pinpoint abnormal patterns that may lead to equipment failures.

Data scientists use the recognized data patterns as the basis for creating predictive models. The models are trained, tested, and then used to identify whether any incipient problems take place, predict when a machine is likely to fail, pinpoint operating conditions and machine usage patterns that lead to failures, etc.

For instance, machine’s condition parameters (e.g., temperature, vibration, etc.), operating parameters (e.g., speed, pressure, etc.), and environmental parameters (e.g., humidity, temperature, etc.) are within normal thresholds. However, combining these parameters and analyzing the joined data set against predictive models helps to reveal that the combination of parameters normal when taken separately can cause, say, a machine’s engine failure. Once a potential failure is identified, the predictive maintenance solution sends a notification to the maintenance specialists, notifying them of potential degradation and recommends a mitigating action. In our smart factory demo, you can see predictive maintenance functionality in action.

We have implemented an IIoT-enabled predictive maintenance solution to improve the reliability of the carriages and avoid excessive maintenance activities. We use data from sensors attached to the potential fault points (roller axle bearings, brake disks, etc.) to gain real-time insights into the condition of the rails and rolling stock and identify root causes of incipient failures.

VR group, a railway company

Dimension 2. Visibility across the manufacturing supply chain

Currently, for 52% of supply chain managers, end-to-end supply chain visibility still seems far-off. However, the prognoses for the adoption of IoT-driven manufacturing supply chain management solutions are quite optimistic: As IDC predicts, by 2020, 80% of supply chain interactions are expected to happen across cloud-based networks. The same source states that the transition towards smart, IoT-enabled supply chain management solutions is predicted to drive supply chain productivity by 15% and increase cost efficiency by 10%.

Smart supply chain management solutions provide manufacturers with real-time insights into the location, status, and condition of every object (be it an individual inventory item on a warehouse shelve or a truck delivering supplies) at any segment of the manufacturing supply chain.

An even bigger value of IoT applied for the manufacturing supply chain optimization is that it enables the shift from knowing whether a particular SKU is available to knowing the status of each item of that SKU.

For instance, with the traditional supply chain management methods, the manufacturers could only get general data about the availability of an SKU:

1,435 items of SKU X are in warehouse 3.

With IoT in the manufacturing supply chain, enterprises get the data about both the location and the properties (e.g. production date, shelf life, etc.) of each individual item of the SKU. For instance:

1,435 items of SKU X are in warehouse 3, of those:

- 1,000 items were produced 12 days ago.

- 435 items were produced 22 days ago.

Along with monitoring the location and the properties of the objects, IoT is applied to monitor the conditions, under which the objects are stored and delivered. Before IoT came into play, the condition of goods could only be monitored once they arrived at the delivery point. Now, the condition of materials, components and goods can be monitored en route, which is especially relevant for the manufacturers of breakable and perishable items (e.g. pharmaceuticals, food, glassware, modern nanomaterials, etc.).

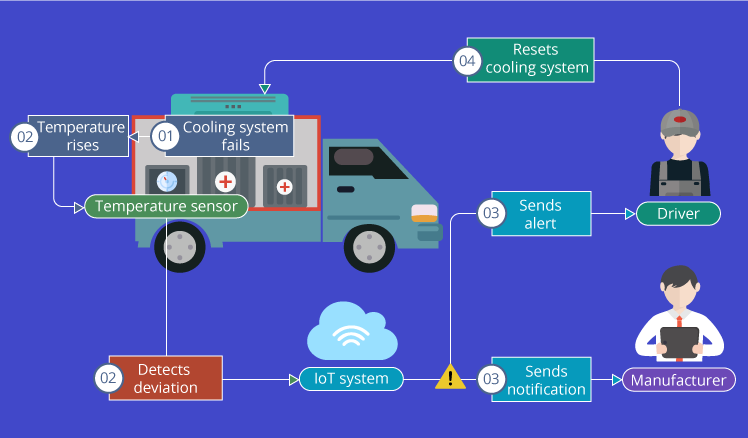

Consider an example of a pharmaceutical company shipping an order to a distribution center via a third-party logistics service provider. Sensors attached to the containers monitor the temperature inside the containers. Suppose, because of a cooling system failure, the temperature inside the containers is starting to rise. A temperature sensor attached to the inner side of the container ‘detects’ the deviation from the recommended threshold. The IoT solution notifies the manufacturer that the delivery conditions have been violated and alerts the driver, who resets the cooling system, thus, preventing spoilage of the transported medicines.

Dimension 3. Visibility into remote and outsourced operations

High logistics costs, increasing demand for customization, the complexity of the global supply chain, and the lack of local talent (hence, the need to outsource) demand the shop floor operations to get distributed.

When an enterprise builds or buys a manufacturing facility in a different city, state or country it still has to maintain its manufacturing and production standards (material testing, industrial automation, predictive maintenance, and other). Impossible to be monitored with traditional methods, the compliance with the production standards can be monitored with IoT.

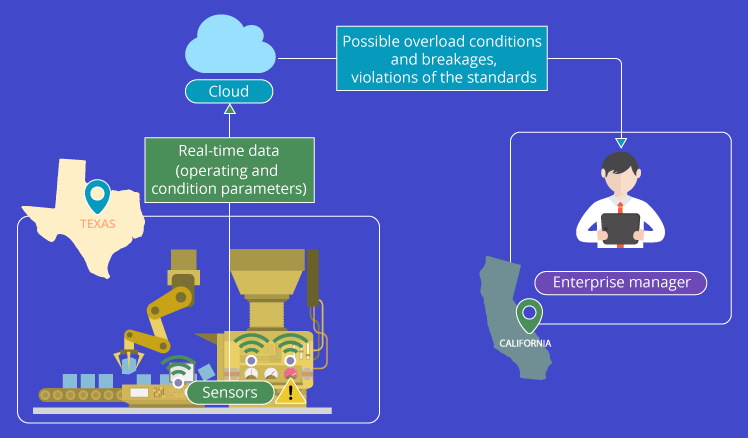

For instance, IoT-based predictive maintenance and timely prediction of potential failures allows scheduling maintenance activities in advance and eliminates the need to keep a local maintenance team. Similarly, IoT-driven utilization monitoring solutions help manufacturers keep an eye on the efficiency of manufacturing operations (by providing real-time equipment efficiency metrics) without direct access to the shop floor.

Another example of how IoT promotes distributed operations is industrial smart, connected products (SCPs). Smart, connected products are complex systems comprising hardware, sensors, connectivity, embedded intelligence, and cloud software.

For example, industrial smart, connected products located at a manufacturing affiliate in Texas enable enterprise managers, say, in California access real-time data about a wide range of the SCPs’ operating (e.g., changes in the temperature of transponders, critically high rotation speed of a milling machine’s spindles, etc.) and condition (e.g., temperature, vibration, etc.) parameters. The managers are informed about possible overload conditions and breakages, as well as violations of the standard operating procedures.

Equal opportunities for small and medium-sized enterprises

By driving improvements in the business and manufacturing processes, IoT provides equal transformational opportunities for small and medium-sized enterprises.

For instance, similar to a large company having several affiliates in the USA and in Mexico, a medium-sized enterprise with the affiliates in Illinois and Texas is geographically distributed, hence, faces similar challenges of distributed manufacturing. Due to reliance on cloud computing and universal, often open-source software, IoT makes digital transformation possible for SMEs.

We have implemented an IoT-based condition monitoring solution to watch over the health and performance of the industrial robots. The solution monitors the condition of machines and alerts technicians if a machine is likely to fail. This allows us predict potential equipment failures and timely mitigate them to carry out a 24/7 production.

An injection molding company with 50 employees

The challenges of IIoT adoption

According to a BCG survey (2016), the toughest challenges US enterprises face starting IoT-enabled digital transformation initiatives include uncertainty about the ROI, data security and privacy issues, the lack of qualified employees, and the integration with the legacy systems. Other significant concerns include the inability to do fast experiments, and missing IoT standards. Let’s look into the key challenges:

- Large investment needs and uncertainty about the ROI. IoT initiatives incur several investments categories - spending on hardware (sensors, gateways), connectivity, cloud storage, administrative labor, and technical support. Businesses have to consider how quickly they can roll out new solutions and how fast it will take for a solution to start generating revenue.

- Data security issues. 58% of IIoT adopters believe IIoT is increasing the risk of cyberattacks (but half of IoT adopters claim that they do not have a plan to prevent losses from possible security threats). As IoT devices become more commonplace, the number of IoT security threats is expected to rise. Gartner predicts that 25% of attacks will involve IoT, while the spending on IoT security will reach $547 million.

- Lack of qualified employees. Inmarsat found that 72% of businesses have a shortage of people at the management level with experience in IoT. Another 80% report a lack of skills among employees in IoT deployment. Another research found the specific skills that are lacking, which include analytics expertise and experience in big data, embedded software development, embedded electronics, IT security and artificial intelligence.

- The integration with operational technologies and legacy systems. The difficulty of rolling out IoT solutions in the manufacturing ecosystems is integrating IT and OT without data losses and security inconsistencies. Ensuring seamless convergence between IT and OT is difficult because in the past, the systems had different objectives, hence, were build based on different technologies and networks. Today, the rapid adoption of Ethernet protocols at the machine level and fast diffusion of web-based user interfaces are gradually easing the integration process, but the challenge is still to be solved.

To wrap it up

The Industrial IoT helps manufacturing enterprises to maximize productivity through maintaining production uptime, reducing costs and eliminating waste. Leveraging IoT data, manufacturers get a better understanding of the manufacturing and supply chain processes, improve demand forecasting, achieve faster time to market, and enhance customer experience. However, considering the scale and the complexity of the Industrial IoT initiatives, successful IIoT adoption requires thoughtful orchestration throughout the IIoT application design and execution segments.

![[TDL110] TDL110 Transport Data Logger](/web/image/product.template/5007/image_512/%5BTDL110%5D%20TDL110%20Transport%20Data%20Logger?unique=e1fdd69)

![[UC100-915M] UC100 Modbus RS485 to LoRaWAN Converter](/web/image/product.template/279988/image_512/%5BUC100-915M%5D%20UC100%20Modbus%20RS485%20to%20LoRaWAN%20Converter?unique=217c80f)