In industrial scenes, as the operating time of mechanical equipment, such as an industrial boiler, becomes longer during operation, the temperature will increase continuously. Therefore, the need of using an industiral temperature sensor to monitor the temperature of the equipment in time can detect problems early and prevent safety accidents.

For example, when the boiler is working, some problems are likely to be seen: abnormal boiler steam, abnormal combustion and abnormal furnace temperature. If the operators do not deal with the problems in time, safety accidents may occur. In this way, to detect anomalies as early as possible and to solve the problem, companies can minimize their losses.

In this topology, EM500-PT100 (transmitter) is installed near the boiler inside the factory and the temperature sensor with a magnet head is placed on the boiler to measure the temperature. By collecting data from the sensors, UG65 gateway is able to forward the data to Milesight IoT Cloud via MQTT or admins can choose to view their data in the monitoring center as well.

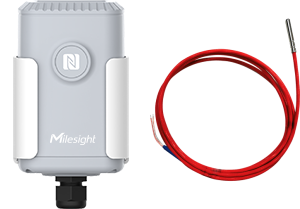

Featured Product

EM500-PT100 Industrial Temperature Sensor

Benefits

Wide Range of Temperature Selections

*Customizable temperature (-200~800℃)

**If the maximum temperature is over 300℃, the PT100 will be non-waterproof.

***If the minimum temperature is below -50℃, then the

maximum temperature should be below 100℃.

5 Head Types Available

The default head type is a straight tube. Other types include armored, SMT, threaded, magnet

Customizable Cable Length

Milesight EM500-PT100 sensor can be easily installed by the printed quick guide provided inside the package and can perform well in any closed areas or outdoors

Excellent Resistance to Chemicals and Oils, Fluids and Gasses

For use in air, water and any benign and corrosive environment (dependent on probe type)