RTD stands for the Resistance Temperature Detector, which contains a resistor that changes rtd resistance value as its temperature changes. The most popular RTD measurement device is the PT100. In the process industry, PT100 sensor is universally and broadly used to measure extreme temperatures covering a wide range from -200 to +800°C.

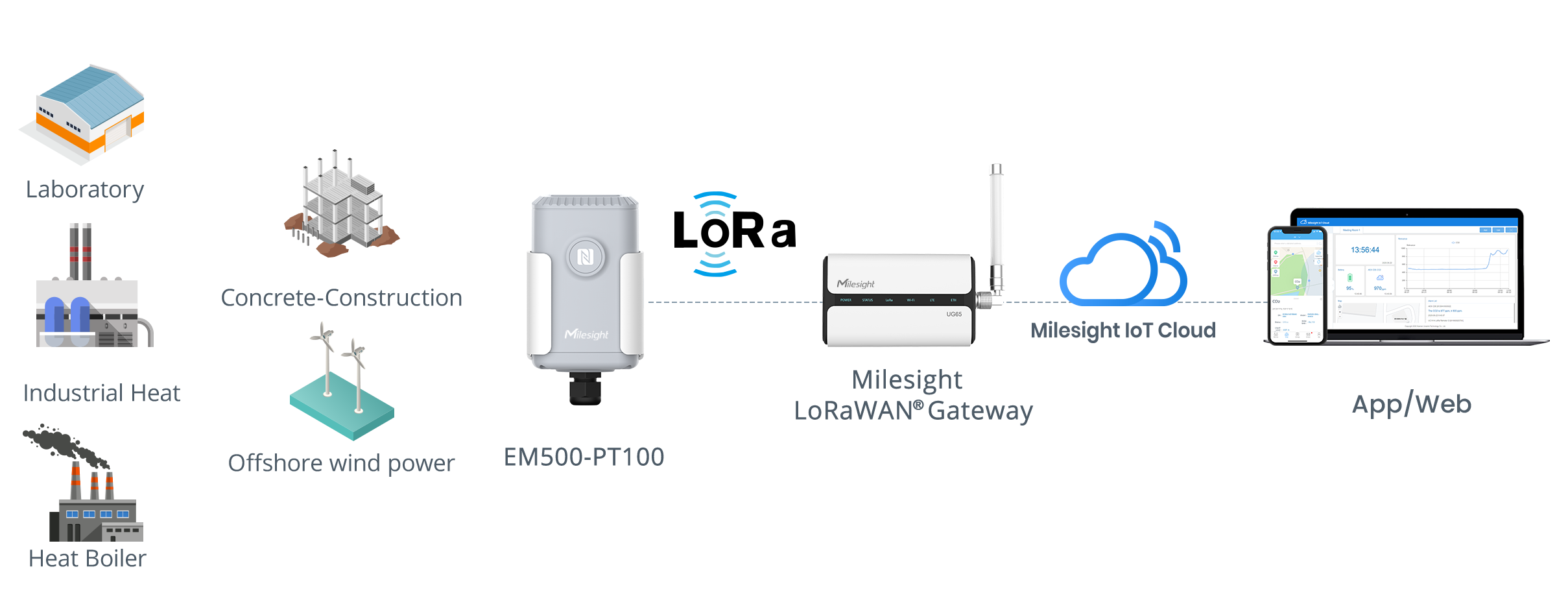

Also, the sensor type indicates two important factors about the sensor. The first factor PT, is the chemical symbol for Platinum and this shows that the sensor is Platinum-made, as platinum is used to this day as the primary element in all high accuracy resistance thermometers. The second factor 100 means the resistance of 100 ohms, which relates to the resistance of the device at 0°C. And in Milesight, powered by one replaceable 19000 mAh Li-SOCL2 battery, this IoT sensor EM500-PT100 is compatible with LoRaWAN® technology.

EM500-PT100 temperature sensor sits at the sweet spot of excellent accuracy, wide temperature range and various applications.

1) Excellent Accuracy for Extreme Temperatures

The PT100 is one of the most accurate temperature sensors. There are three different ways to measure resistance, which are 2-wire, 3-wire or 4-wire connection. The 2-wire connection is generally suitable for very low accuracy measurements, because any wire resistance or connection resistance will bring error to the results.

Any normal process measurement should be done using 3-wire connection at least. And Milesight EM500-PT100 is taking use of 3-wire connection measurement for compensating the cable resistance, so as to guarantee the accuracy of collected temperature data.

2) Platinum Probes for Wide Temperature Range

Platinum has a positive resistance temperature factor; resistance increases with rising temperature. Although platinum is a precious metal and therefore very expensive, it delivers greater linearity and stability than any other material.

Milesight EM500-PT100 measures temperature range from -50 to +200°C by default and is able to expand that range from -200 to higher temperature +800°C through different sub-models.

3) Adapted Design for a Multitued of Applications

The EM500-PT100 comes with a couple of types of high accuracy platinum resistance thermometer probes.

The straight tube type of EM500-PT100 probe that can be used in the common industrial sectors such as measuring operations in extremely humid atmospheric condition.

Besides that straight tube type, you can also get some other types of probe including the armoured, the pressure ring, the magnet, the threaded and SMT, etc by customizing service. They can also help EM500-PT100 sensors work smoothly in applications affected by vibrations, and minimize the impact from turbines, pumps, compressors and other industrial equipment.

Furthermore, the independent lithium battery inside this sensor makes it relatively immune to electrical noise and therefore is well suited for temperature measurement in harsh industrial environments.

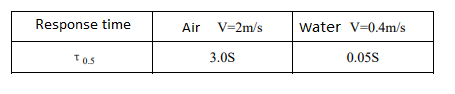

4) Response time

When temperature changes with stages, output of thermocouple will be changed to 50% of this stage variation, required time is called heat response time, represented in τ0.5.

The factors that affect τ0.5 are related to the material, diameter, and thickness of the protective tube, as well as its structure, installation method, insertion depth, and the flow rate and type of the measured medium.

Typical data values of component response time are as follows:

5) RTD vs Thermocouple / Thermistor

Finally, another frequently asked question by customers is the differences between RTD and thermocouple or thermistor. Well, each kind of temperature sensor has its own marketing position and best suited circumstances. The Resistance Temperature Detector offers several advantages such as:

- The wide temperature range

- Better accuracy than thermocouples

- Long-term stability

- High Accuracy: Class A Per IEC 60751

Benefits

As a professional sensor manufacturer, Milesight EM500-PT100 temperature sensor gives superior performance of hardware and high accuracy data.

- Easy Configuration with NFC technology

- Easy Deployment with Wall Mounting/ Pole Mounting/ DIN RAIL

- IP67 weatherproof and waterproof housing

- For use in air, water and any benign and corrosive environment (dependent on probe type)

- Max. 10 years battery life (dependent on use)

- Milesight offers a wide variety of probes in various configurations

- The EM500-PT100 resistance thermometer doesn’t require additional calibration

- Platinum RTD is the most linear, stable and accurate of all RTD’s without measurement errors

Typical Applications

- Ultra Cold Freezers (-80°C)

- Refining, petrochemical

- Power & energy industries

- High-vibration applications: turbines, pumps, compressors

- Plant Processing

7 Steps to Choose A Suitable Temperature Sensor

Let’s go over the top 7 factors that you need to consider when picking up the right Platinum Resistance Thermometers or RTDs or Pt100 rtd sensor for your application.

1) Element Type

Do you know the RTD element type? Besides the platnium PT100 or PT1000, other materials such as nickel, nickel-iron alloy and copper have also been used for RTDs. Regardless of the medium that you are connecting the RTD sensor to, this factor must be firstly confirmed.

2) Measuring Medium

Will you work the sensor for a gas, liquid or material’s surface measuring? Where will you deploy the probe? Do you have to put the probe inside something or fasten with something?

3) Temperature Range

This is the fundamental factor as it determines the element type and the submodels from EM500-PT100 model from -200 to 800°C

4) Deployment Location

What type of probe can help you best fix the RTD, which depends on the location, such as wall mounting, pressure ring, magnetic, SMT, etc.

5) Working Environment

Does the IP67 rating and anti-corrosive protection enough to you? Do you need it to be ATEX approved, safe to food production, against vibration?

6) Physical Considerations

What are the length, diameter and size requirements? Does is need to be bent or extremely long?

7) Wire Connection

You also need to ensure if 2 wire connection is enough to you? Or you need more accurate data that provided by 3 wire or 4 wire connect?

If you can answer the above question, you can make a right decision mostly. Do you want to know more about EM500-PT100 sensor? Why not join our webinar or download the datasheet now.